Located in Dongguan, Guangdong Province, WJ-Lean Technology Co., Ltd. has gained a reputation as a leading manufacturer of automation equipment and machine vision system solutions. With a global market layout and comprehensive service agencies spread across several countries, the company is well equipped to service the needs of clients all over the world.

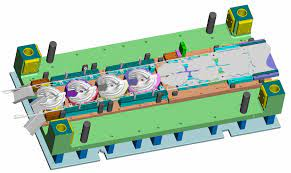

The custom thermoform tooling and mold design department will focus on the design and manufacture of molds for thermoforming with a keen emphasis on quality, precision, and customization. Thermoforming is a manufacturing process that involves heating a sheet of plastic to a specific temperature, and then stretching it over a mold to create a specific shape. The process is used to make a wide range of products, including packaging materials, medical devices, and automotive parts.

To ensure that their custom thermoform tooling and mold designs meet the highest industry standards, WJ-Lean Technology Co., Ltd. has assembled a team of experienced tool die makers that are well versed in the latest molding techniques and technologies. The team has access to the latest equipment and tools to ensure that every mold produced is of the highest quality.

"Our new custom thermoform tooling and mold design department is an important step in expanding our range of services to our clients," said a company spokesperson. "We recognize that the molding industry is constantly evolving, and we are committed to staying ahead of the curve by investing in the latest technologies and hiring experienced professionals. The launch of this new department is a testament to our commitment to offering the highest quality solutions to our clients."

Customers will benefit from the company's custom thermoform tooling and mold design department in several ways. Firstly, customers will be able to work closely with the tool die makers to create molds that are tailored to their specific needs. This means that the molds will be optimized for the production of their specific product, leading to increased efficiency, quality, and cost savings.

Secondly, because the department is in-house, customers can expect faster turnaround times and greater flexibility in ensuring the quality and consistency of their products. The team can work closely with the production team to ensure that the molds are performing optimally and pass any necessary quality control checks before being put into full production.

In conclusion, the launch of WJ-Lean Technology Co., Ltd.'s new custom thermoform tooling and mold design department is a significant investment in the future of the company. By taking a proactive approach to the molding industry and investing in the latest technologies and experienced professionals, the company is well positioned to deliver high-quality custom thermoform tooling and molds that exceed client expectations.